Sarvesh multi plast india private limited

Sarvesh multi-plast India Private Limited name in the field of UPVC and PVC manufacturing in India.Our Company has earned a reputation to delivering high quality products and professional services.Our journey began in 2009 in the state of Tamilnadu, with the vision of our founder. Mr. Goivndasamy, To establish a business that would cater to the growing infrastructure needs of Tamilnadu. Today, our success speaks for itself, as we have expanded our influence across IndiaOver the last thirteen years, the Sarvesh group has built two manufacturing factories in the Erodedistrict with an impressive annual production capacity of forty thousand metric tonnes (40000 perannum)As a result, Sarvesh Multi Plast India Private Limited has emerged as one of the top manufacturers of UPVC, PVC, Foamboard & WPC in the country. Our diverse range of products includes sub-brands like Eroline, Erowood, Whitewood, and Fixit & Erolam Our commitment towards quality and customer satisfaction has been the driving force behind our growth and success. At the Sarvesh multi Plast India Private Limited. We adhere to stringent quality standards and invest in cutting-edge technology to ensure that our products meet the highest industry standards our team of professionals is dedicated to providing exceptional service and we strive to build long-lasting relationships with our clients We take pride in our achievements and look forward to continued growth and success in the year to come. As we expand our reach. We remain committed to our core values of quality, Innovation and customer satisfaction.

About Eroline

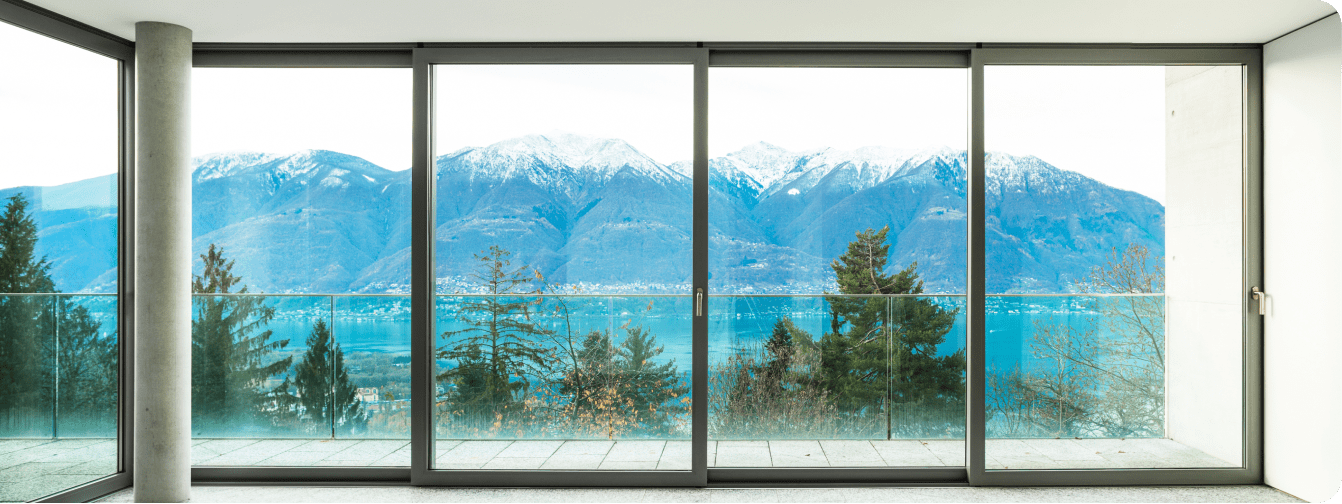

Welcome to Eroline, where superior UPVC window and door profiles meet innovative design. We bring more than 15 years of industry experience to the forefront as the company of Sarvesh Multi Plast India Private Limited. Eroline represents our constant commitment to providing premium UPVC products enhanced with state-of-the-art German Technology. Over the past 15 years, Eroline has worked to perfect UPVC profiles, earning a reputation for excellence, dependability, and innovation. We incorporate well-known German technology into our production to guarantee accuracy, toughness, and innovation in every Eroline profile.Our dedication to excellence is evident in profiles that are above industry standards. Durability, energy efficiency, aesthetic appeal, environmental responsibility, low maintenance, customizability, and expert support are all features offered by Eroline., Eroline wants to be the trusted name in high-quality UPVC window and door profiles. Join us as we transform spaces through the transformative force of German technology

MD Desk

The development of the country remains the primary priority, and the expansion of Sarvesh Multi Plast India Private Limited will follow naturally. The company is committed to contributing to the growth of Tamil Nadu and India as a whole, and it strives for the highest quality at all stages of production. Sarvesh gratitude its hardworking employees for their contributions to the company's growth and improvement. The company also understands the importance of its manufacturing units and strives to reduce its carbon footprint.

“We aim to be a part of India's infrastructural development, and we are proud that Sarvesh Multi Plast India Private Limited has contributed to building dream homes for millions of Indians”

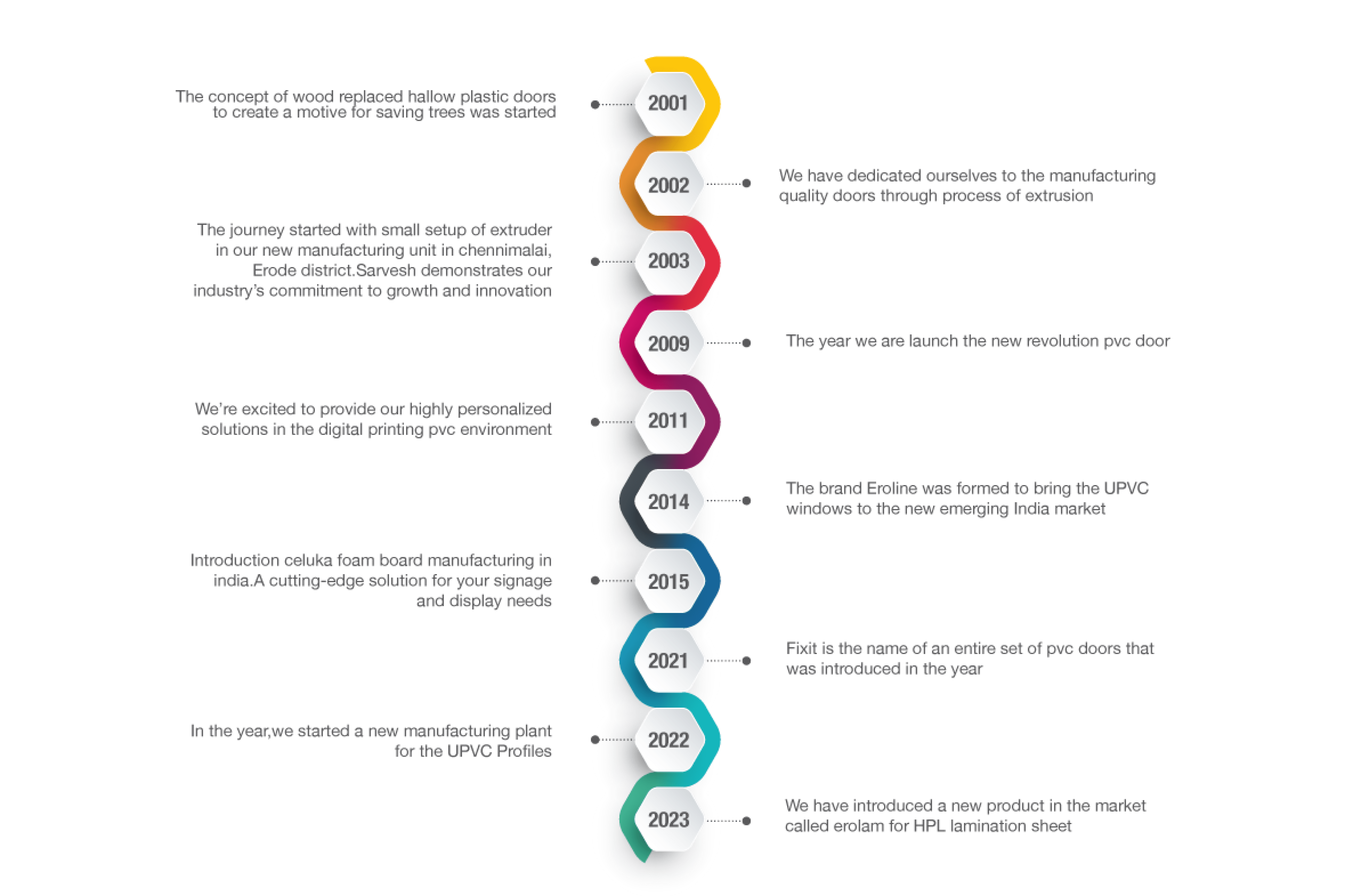

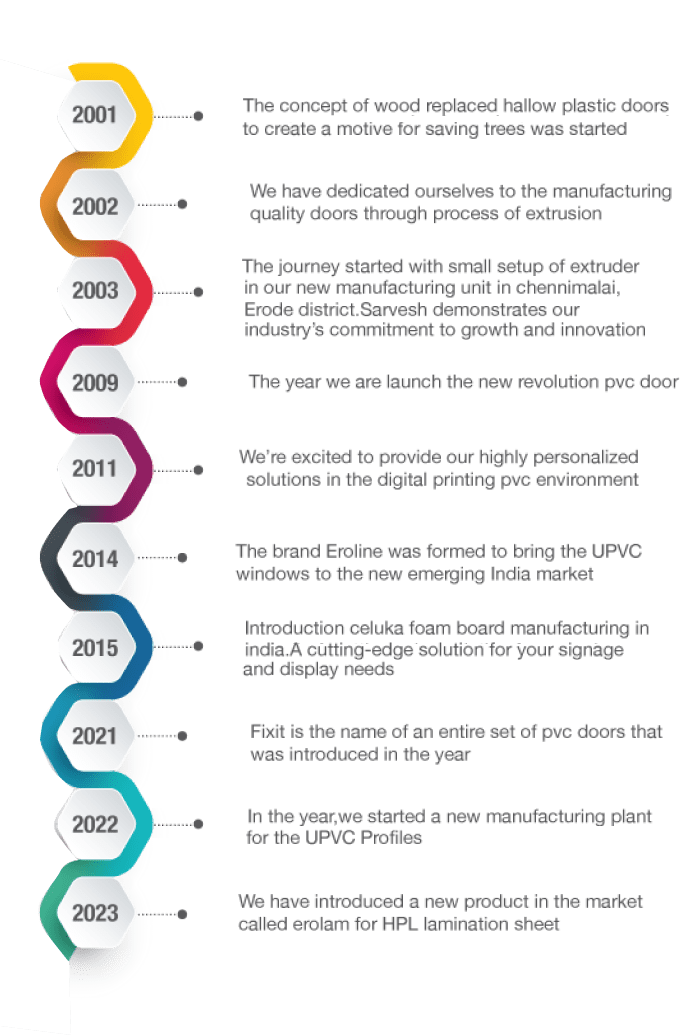

Time Line

Infrastructure

Extrusions

The UPVC extrusion process involves melting UPVC pe lets or powder in an extruder and rapidly cooling it as soon as the material leaves from the tool. All our uPVC profiles are manufactured with german technology with the right precision. The process of maintaining and improving the production process is done completely through data

40,000

MT/annum Production Capacity15

Years Of Experience In PVC Manufacturing Industry63

Tooling03

Units04 Branches

Chennai,Bangalore, Hyderbad,GhaziabadTool Room

uPVC tooling plays a vital role in the fabrication of high-quality uPVC windows and doors. With precision engineering, advanced technology, and a focus on efficiency, uPVC tooling enables manufacturers to produce durable, energy-efficient, and aesthetically pleasing products that meet the demands of today's construction industry.

Discover the precision tools and equipment designed to ensure the quality and efficiency of UPVC profile production. With our state-of-the-art tools, we empower manufacturers to craft top-notch profiles for diverse applications

Compounding

The UPVC high-speed mixer is designed to blend UPVC resin, stabilizers, plasticizers, and other additives uniformly and efficiently. These mixers feature high-speed mixing blades or elements that facilitate rapid dispersion and distribution of additives throughout the resin matrix. The high-speed mixing action ensures homogeneity of the mixture, preventing inconsistencies in the final product.

- Precision: Automated UPVC mixers can precisely control the mixing ratios of raw materials, ensuring consistency in the quality of the final product. This precision helps in maintaining product standards and reduces material waste

- Automation eliminates the need for manual intervention in the mixing process, leading to increased efficiency , PLC & SCADA based system give precise control

Benefits :

Quality Assurance/Laboratory

At Sarvesh, our reputation is built on the exceptional quality of our products across our entire range. This is made possible by our substantial investments in state-of-the-art testing equipment, which ensures the highest standards for both the finished product and the raw materials used in its production. Our windows undergo thorough testing and verification by renowned laboratories such as SGS and CIPET to ensure their durability and sustainability for decades

Quality- uPVC, or unplasticized polyvinyl chloride, stands as a stalwart material in modern construction, renowned for its versatility, durability, and eco-friendliness. This polymer composite, composed primarily of vinyl chloride monomers, undergoes a unique manufacturing process, resulting in a material devoid of plasticizers, hence the term “unplasticized.” Sarvesh internal quality follow the BIS -19753 STATDARD & india”s first ISI certified company Sarvesh lab is fully equipped BY various equipments those are following EN 12608 & 17953

- Dimensional accuracy

- LAB values

- Mass of profile as per standard

- Straightness

- Mechanical properties

- Thermal properties

Finished Goods Inventory Area

For Sarvesh Multi-Plast, a large finished goods area is crucial, providing ample space to store and organize products. This streamlines logistics, ensuring Sarvesh Multi-Plast's products are readily available for distribution. The area's capacity to accommodate production fluctuations helps Sarvesh Multi-Plast meet customer demand effectively. Overall, this spacious finished goods area contributes significantly to the efficiency and effectiveness of Sarvesh Multi-Plast's operations.

In house testing Facilities

• Density

• Color Test

• Glossy Point

• Heat Reversion

• Heat Aging

• Impact Strength

• Charpy Impact

• Tensile bending

• Vicat softening

All Weather Protection

All Weather Protection

Quality Hardware

Quality Hardware

Double Seal System

Double Seal System

Strong and Robust Frame

Strong and Robust Frame

CONTACT US